Back to top

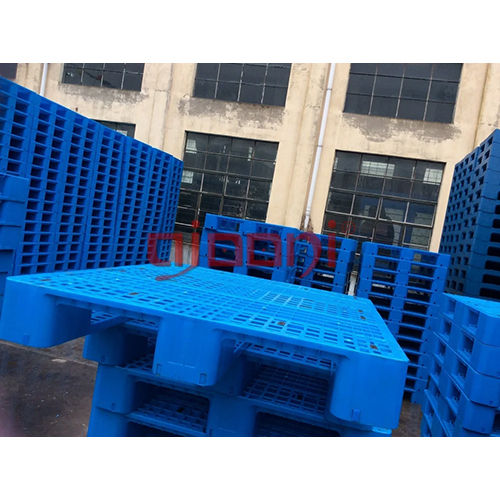

A leading choice of the market to avail storage products such as Drum Storage Racks, Industrial Storage Racks, Stand Display Racks, FIFO Flow Rack, Cold Storage Racks, Material Handling Racks, Poly Pallet, etc.

A leading choice of the market to avail storage products such as Drum Storage Racks, Industrial Storage Racks, Stand Display Racks, FIFO Flow Rack, Cold Storage Racks, Material Handling Racks, Poly Pallet, etc.

HOT PRODUCTS

For usage in a broad range of industries and applications, Ajooni Storage Systems provides storage, archiving, and material handling solutions. We deliver a wide range of storage solutions from simple to high-quality shelving, effective filing and storage in offices, expert archive systems, pallet racking and mezzanine storage spaces. Our products such as Drum Storage Racks, FIFO Flow Rack, Cold Storage Racks, Material Handling Racks, Industrial Storage Racks, Stand Display Racks, Poly Pallet, etc. make us popular in the industry.

Our company began operations with the goal of producing an extensive array of storage systems that would provide clients with comprehensive solutions for their small- to large-scale storage needs. Our systems are built with the most cutting-edge features available, guaranteeing the highest standards of quality. The QC unit operates at full tilt in order to raise the bar to the highest possible industry standards.

Quality

Our company is famous in the market, we have the eminent ISO 9001:2015 certification. We are one of the few businesses that have received the certification in a short time period. Every one of our items is built with quality. With measurable metrics, we consistently and timely fulfil and enhance our promises to all stakeholders.

Principles of Quality Management

We have adopted certain principles of Quality Management and they are cited below:

Before any finished product is released from our factory, the following procedures are followed in the manufacturing process to guarantee supreme quality.

Details of Pre-treatment and Painting Methods.

Oil residue remains on items following necessary machine operations such as shearing, pounding, and bending. In order to guarantee a high-quality paint finish and an extended product life, it is imperative to remove this.

In order to accomplish this, every manufactured component will undergo a complex surface treatment procedure that involves a four-step, seven-tank specific anti-corrosion treatment that includes the following steps:

Degreasing (Alkaline Cleaning)

The metal surfaces of the rack components will be cleaned of oils and other semi-solids using this procedure. For this procedure, it is necessary to guarantee the proper concentration of sodium metasilicate, soda ash, tri-sodium phosphate, and caustic soda within well monitored temperature restrictions. This procedure needs to be followed in accordance with IS 6005 of 1970.

Removal of alkaline impurities

To get rid of any alkaline contaminants from the surface of the rack components, rinse them in water after degreasing.

Pickling (Acid cleaning)

Following degreasing and washing, a sulphuric acid solution will be used to acid clean every rack component, removing any remaining rust and scales. The procedure must be followed in accordance with IS 6005 of 1970.

Removal of acidic impurities

The components must be completely washed in water to get rid of any remaining contaminants after acid cleaning.

Phosphating

After the rack components' metallic surfaces have been cleaned, they must be treated in a phosphoric acid tank to undergo a phosphating procedure that will shield the surface against future corrosion. To give the phosphate coating a fine texture, sodium nitrite will be employed as an accelerator. Process compliance with IS 6005 & 3618 of 191996, class 'D', is required.

Water Rinsing

All of the components must be completely washed in water after phosphating in order to get rid of any remaining sodium nitrite and phosphoric acid.

Passivation

Following a thorough rinse, each component will passivate with diluted chromic acid. A light chromate layer left over from the passivation will improve the metal's resistance to corrosion, dampness, and paint adherence.

Following the completion of chemical treatment process, premium paints from reliable suppliers are sprayed on or dipped into the goods. To guarantee a long lifespan and high quality finish, the products are oven baked for 30 minutes at 120 degrees in our dedicated oven after painting.

Clientele

Our company began operations with the goal of producing an extensive array of storage systems that would provide clients with comprehensive solutions for their small- to large-scale storage needs. Our systems are built with the most cutting-edge features available, guaranteeing the highest standards of quality. The QC unit operates at full tilt in order to raise the bar to the highest possible industry standards.

Quality

Our company is famous in the market, we have the eminent ISO 9001:2015 certification. We are one of the few businesses that have received the certification in a short time period. Every one of our items is built with quality. With measurable metrics, we consistently and timely fulfil and enhance our promises to all stakeholders.

Principles of Quality Management

We have adopted certain principles of Quality Management and they are cited below:

- Leadership

- Customer focus

- Continual improvement

- Right process approach

- Involvement of people

- System approach to management

- Mutually beneficial supplier relationship

- Factual approach to decision making

Before any finished product is released from our factory, the following procedures are followed in the manufacturing process to guarantee supreme quality.

Details of Pre-treatment and Painting Methods.

Oil residue remains on items following necessary machine operations such as shearing, pounding, and bending. In order to guarantee a high-quality paint finish and an extended product life, it is imperative to remove this.

In order to accomplish this, every manufactured component will undergo a complex surface treatment procedure that involves a four-step, seven-tank specific anti-corrosion treatment that includes the following steps:

Degreasing (Alkaline Cleaning)

The metal surfaces of the rack components will be cleaned of oils and other semi-solids using this procedure. For this procedure, it is necessary to guarantee the proper concentration of sodium metasilicate, soda ash, tri-sodium phosphate, and caustic soda within well monitored temperature restrictions. This procedure needs to be followed in accordance with IS 6005 of 1970.

Removal of alkaline impurities

To get rid of any alkaline contaminants from the surface of the rack components, rinse them in water after degreasing.

Pickling (Acid cleaning)

Following degreasing and washing, a sulphuric acid solution will be used to acid clean every rack component, removing any remaining rust and scales. The procedure must be followed in accordance with IS 6005 of 1970.

Removal of acidic impurities

The components must be completely washed in water to get rid of any remaining contaminants after acid cleaning.

Phosphating

After the rack components' metallic surfaces have been cleaned, they must be treated in a phosphoric acid tank to undergo a phosphating procedure that will shield the surface against future corrosion. To give the phosphate coating a fine texture, sodium nitrite will be employed as an accelerator. Process compliance with IS 6005 & 3618 of 191996, class 'D', is required.

Water Rinsing

All of the components must be completely washed in water after phosphating in order to get rid of any remaining sodium nitrite and phosphoric acid.

Passivation

Following a thorough rinse, each component will passivate with diluted chromic acid. A light chromate layer left over from the passivation will improve the metal's resistance to corrosion, dampness, and paint adherence.

Following the completion of chemical treatment process, premium paints from reliable suppliers are sprayed on or dipped into the goods. To guarantee a long lifespan and high quality finish, the products are oven baked for 30 minutes at 120 degrees in our dedicated oven after painting.

Clientele

|

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS